Reliability, safety and efficiency are non-negotiable factors in industries, so the selection of pumping systems can be the difference. Oil and gas, petrochemicals, and chemical processing plants work in one of the harshest and most challenging environments in the world, and their equipment must always be up to the task. That is why API 610 pumps of GTC Fluid Technology (Shanghai) Co., Ltd. have gained credit among businesses worldwide. These pumps have been constructed within the high standards of the American Petroleum Institute, providing a high degree of durability, safety, and performance that prevails in overseas markets. Let's click to learn more about GTC api610 pump for making a good decision.

Constructed To International Standards

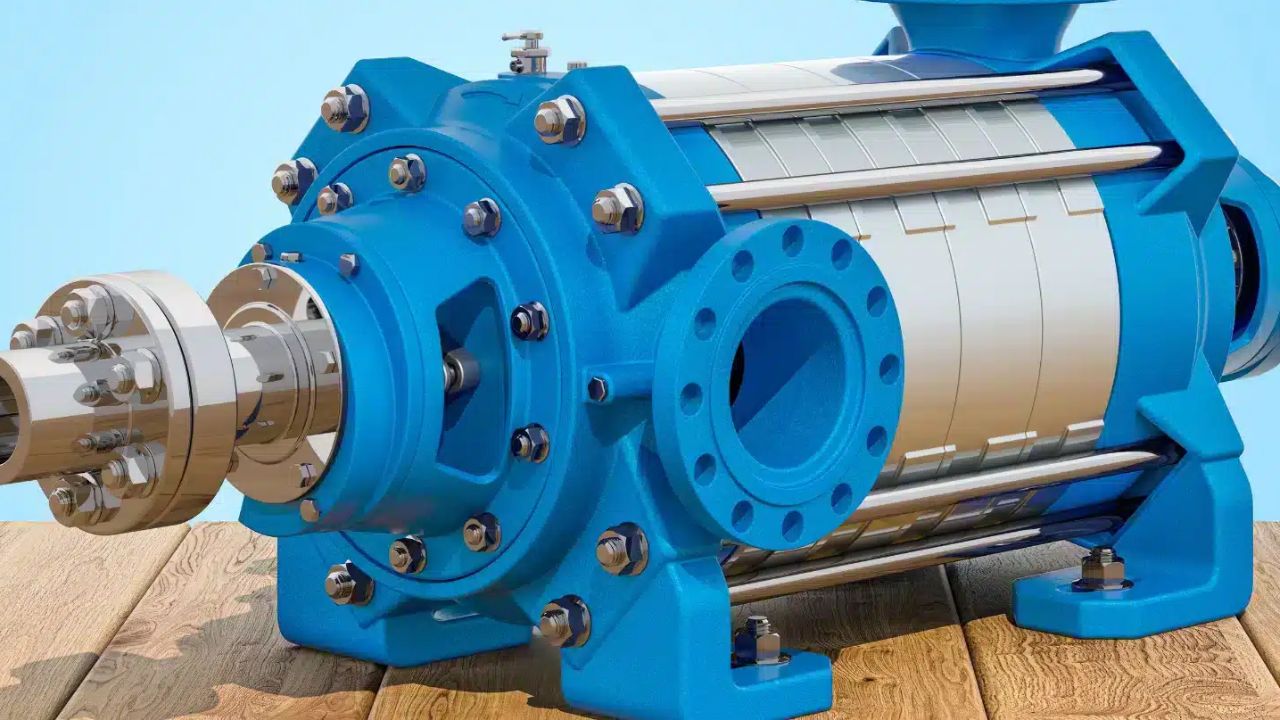

Centrifugal pumps employed under critical applications are governed by API 610, which is the global standard in the field. It provides rigorous design, construction, and testing requirements so that the pumps are able to function under intensive temperatures, high pressures, and corrosive conditions. GTC produces its pumps in total accordance with API 610 and, as a result, all its products out of the production line can be used in the most demanding conditions. Such compliance with international standards helps end-users to be sure that GTC pumps are not only powerful but also internationally recognized as safe and reliable solutions.

Harsh Environment Engineering

One of the factors that makes GTC API 610 pumps reliable worldwide is the ability to operate under the harshest operating conditions. Whether it be corrosive chemicals, volatile hydrocarbons or hot temperature fluids, these pumps are made using materials and engineering practices that ensure reliability and smooth working. It is designed to meet the requirements of a specific project by being available in a choice of carbon steel, stainless steel, duplex stainless steel and super duplex stainless steel. GTC achieves this through aligning material choice with process requirements. Its pumps have a high level of reliability in environments where failure will not only be costly but also hazardous.

Comprehensive Testing and Quality Assurance

Design is not enough to gain trust, but performance that is demonstrated. Before delivery, every GTC API 610 pump undergoes a comprehensive series of tests. The integrity of casing is checked with hydrostatic tests, the ability to work with flows and pressure is checked with flow and performance tests, and the stability of the work under extended conditions is checked with mechanical running tests. This high-quality assurance regime will subject the pumps to rigorous testing that will result in the equipment being installed and working as desired. This level of scrutiny provides customers worldwide with the confidence that they are receiving pumps that can be serviced, any time and with maximum reliability.

Minimizing Risk and Operating Cost

Safety and reliability are tied. Even the slightest equipment malfunction in industries that are exposed to toxic, flammable or high-pressure media can create hazards. GTC API 610 pumps are designed in a way that limits leakages and mechanical problems to safeguard human life and the environment. Meanwhile, the powerful construction decreases the number of maintenance interventions, prolonging the service period and decreasing the overall operating expenses. These pumps are reliable in terms of ROI to companies that are concerned with long-term value and continuous operations.

Global Applications Across Industries

Customers across the world have confidence in GTC API 610 pumps because they have worked effectively in various industries. They are utilized in crude oil transfer, water injection and distillation feed in oil and gas. In petrochemicals, they are working with aggressive chemicals, volatile organic compounds and high-temperature heat transfer fluids. Chemical processing plants rely on them for charge pumps, reactor feed systems, and safe transfer of corrosive media. This flexibility makes them the choice of companies in the international marketplace that want to find a solution that could be implemented in various spheres of their work.

A Partner for Worldwide Clients

In addition to product performance, GTC has gained a reputation as a trusted partner to its clients. The company has a concentration in terms of quality assurance, customer service and technical know-how, and in order to meet the needs of each project, it collaborates with international clients. Through its capacity to provide good engineering and attentive services, GTC is enhancing its position not only as a supplier of pumps but also as a reliable partner in the success of its industries.

Conclusion

GTC API 610 pumps have gained a name based on international standards compliance, sound engineering, and quality commitment. They have been a reliable partner to companies around the world due to their capability to provide safe, reliable, and cost-effective services in some of the most rigorous industries across the globe. To companies that cannot afford downtime or compromise, API 610 pumps offered by GTC are not just equipment, but a guarantee of reliability, longevity and value.