Automated sorting systems are crucial for streamlining material handling processes across various industries, from recycling to manufacturing. One of the key challenges in these systems is effectively separating metal contaminants from the materials being processed. Integrating magnetic head pulley into automated sorting systems offers a practical solution. These pulleys efficiently capture ferrous materials as they pass through the conveyor, preventing contaminants from reaching sensitive equipment or compromising product quality. In this article, we will explore how magnetic head pulleys can enhance the efficiency and accuracy of automated sorting systems, ensuring cleaner materials and smoother operations.

How to Integrate Magnetic Head Pulleys into Automated Sorting Systems

Integrating magnetic head pulleys into automated sorting systems improves metal contamination removal and material flow. Easy to install, they fit seamlessly into existing systems, offering practical solutions for industries like recycling, mining, and manufacturing. Here are key integration steps to follow.

Step 1: Assess the Material Flow and System Requirements

Before integrating magnetic head pulleys, assess the characteristics of the materials being handled, including their size, volume, and ferrous contamination levels. Consider factors like conveyor speed, material flow, and the types of contaminants to select the appropriate size, strength, and configuration of the pulley for optimal performance.

Step 2: Choose the Right Magnetic Head Pulley

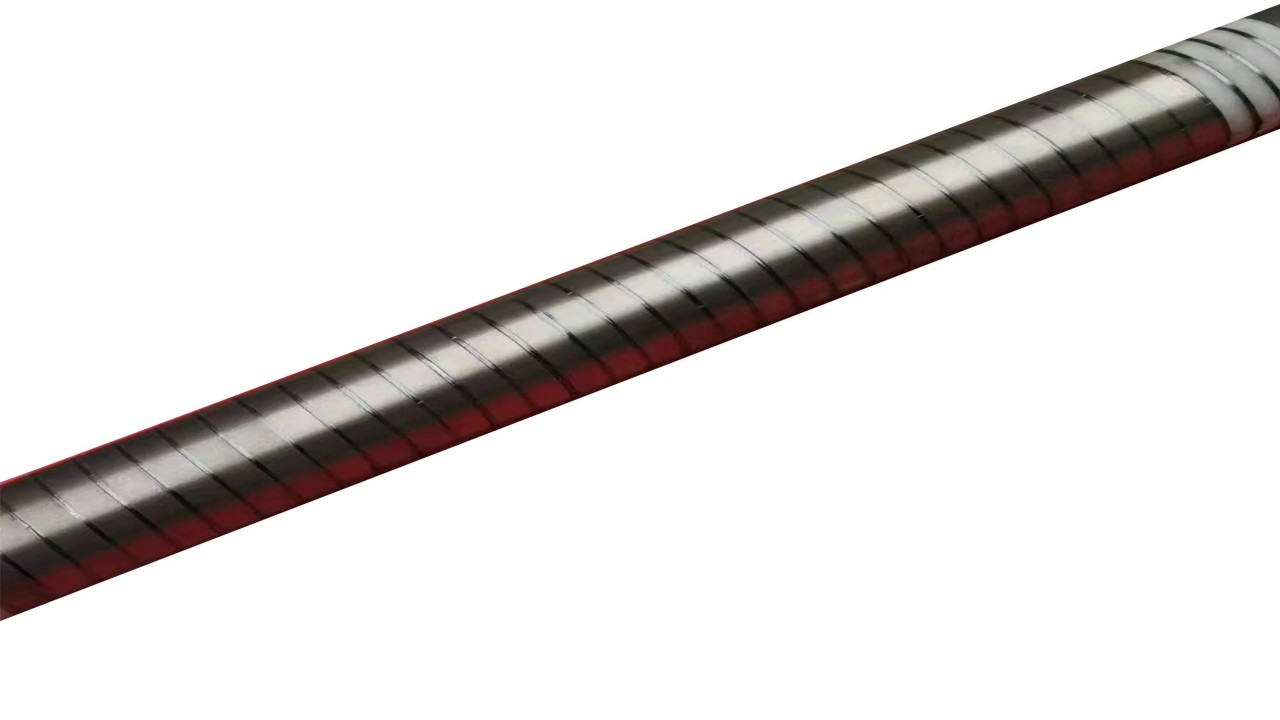

Magnetic head pulleys come in various strengths, sizes, and configurations. Choose the one that matches the intensity of the magnetic field required to attract and separate ferrous contaminants. For heavier debris, a stronger magnetic pulley (such as one made with high-grade neodymium magnets) may be necessary. Consulting with a provider like Jinhong ensures the best match for your sorting system.

Step 3: Install the Magnetic Head Pulley into the Conveyor System

To install the magnetic head pulley, replace the standard pulley at the head of the conveyor with the magnetic version. Position the pulley at the point where the material enters the system for maximum effectiveness in metal removal. The pulley should be aligned so that the material passes directly under the magnetic field for optimal capture of ferrous contaminants.

Step 4: Set the Correct Gap Between Pulley and Material

Adjust the gap between the pulley and the material flow to ensure effective ferrous contaminant capture. If the gap is too large, the magnetic field might not be strong enough, while a gap that is too small can cause wear on the pulley. Proper gap setting is crucial for maintaining optimal performance.

Step 5: Monitor and Maintain the Magnetic Head Pulley

Regularly monitor the performance of the magnetic head pulley after installation. Check for metal debris buildup, verify alignment, and ensure the pulley is free from any debris that could affect its functionality. Periodic cleaning and maintenance help maintain maximum efficiency and ensure effective metal removal over time.

Step 6: Integrate with Other Sorting Components

To enhance sorting system performance, integrate the magnetic head pulley with additional technologies like vibratory feeders, air classifiers, or optical sorting machines. This integration helps ensure a comprehensive contaminant removal process and improves the purity of the sorted materials.

Conclusion

Integrating magnetic head pulleys into automated sorting systems enhances efficiency by effectively removing ferrous contaminants from materials. This protects equipment, improves sorting accuracy, and ensures higher-quality products. Magnetic head pulleys can be easily incorporated into existing systems, offering a cost-effective solution for industries seeking to optimize their operations. Companies like Jinhong provide reliable, high-quality magnetic head pulleys that help improve the performance of automated sorting systems. With their ability to streamline processes, magnetic head pulleys contribute to reducing downtime, increasing productivity, and maintaining material purity in various industrial applications.