Volumetric feeders are essential components in various industrial processes, particularly those involving plastic processing. These machines precisely control the flow of bulk solids by consistently delivering a predetermined volume of material with each cycle.

Understanding their functionality and significance is important for optimizing production processes and ensuring product quality. Therefore, this article is your guide to understanding volumetric feeders, their working principles, benefits, and application.

What are Volumetric Feeders?

Volumetric feeders are precision instruments utilized in plastic processing to dispense predetermined amounts of material accurately into a production process. These feeders operate based on volume and deliver a specified quantity of material per unit of time.

Working Principles of Volumetric Feeders

Volumetric feeders employ a rotating mechanism to measure and dispense bulk solids accurately. There are two main types of volumetric feeders:

Rotary Vane Feeders

These types of feeders utilize a rotating vane within a cylindrical housing. As the vane spins, it captures a specific volume of material and discharges it through an outlet. The speed of rotation and the geometry of the vane determine the dispensed volume.

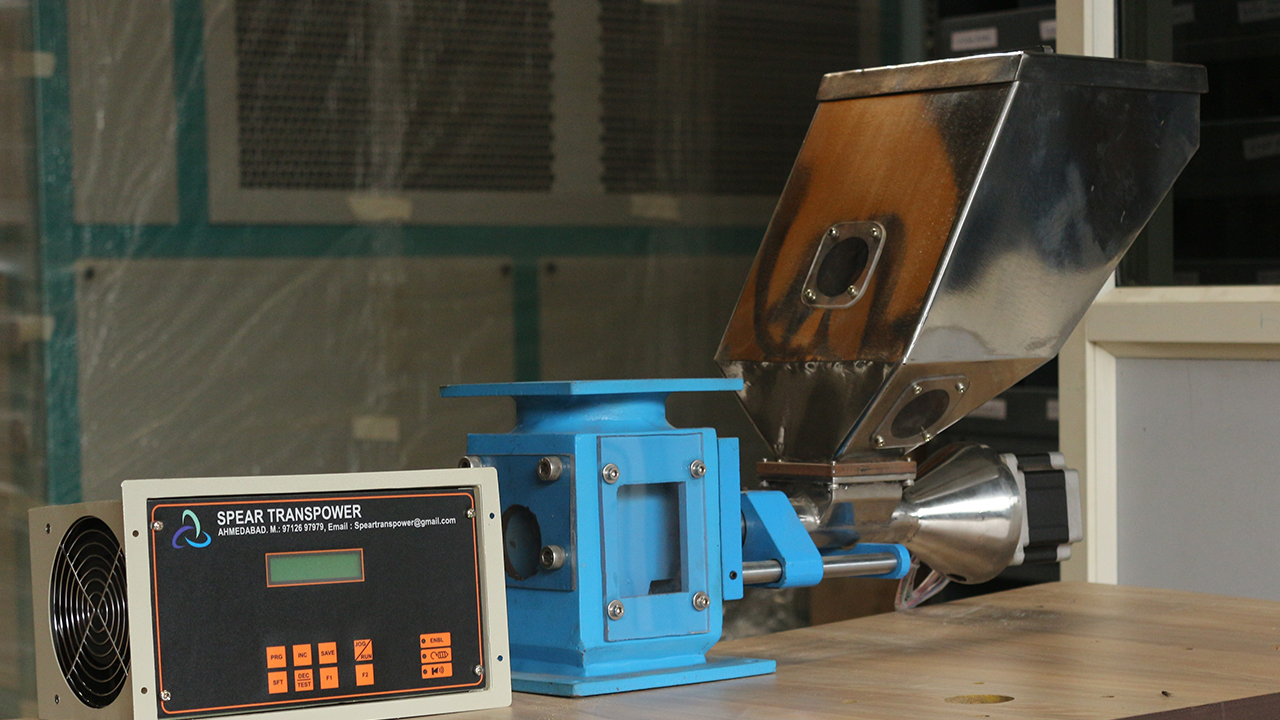

Screw Feeders

Screw feeders feature a screw auger that rotates inside a trough. The auger continuously conveys material along its length, with the feed rate being controlled by the screw speed and the pitch of the auger.

Benefits of Utilizing Volumetric Feeders

Volumetric feeders offer several advantages for industrial applications. They provide consistent and repeatable dosing of bulk solids to ensure precise material control within a process. Moreover, these feeders are generally easy to operate and require minimal maintenance. This makes them user-friendly for various production environments.

In addition, volumetric feeders can handle a wide range of bulk solid materials, from free-flowing powders to slightly cohesive granules. They are typically more affordable than gravimetric feeders, and their feed rate can be adjusted to meet specific process requirements.

Applications of Volumetric Feeders

Volumetric feeders are employed in a diverse range of industries and applications, including:

Plastics Processing

Volumetric feeders accurately dispense plastic pellets or granules into extruders, which produce films, sheets, pipes, and other plastic profiles. They can control the flow of plastic pellets or flakes into blow molding machines. Also, they can be integrated into blending systems.

Food and Beverage

They also precisely dispense ingredients like grains, cereals, spices, and powders in food manufacturing. They control the feeding of grains, powders, and other dry ingredients in food and beverage production processes.

Chemical and Pharmaceutical

Volumetric feeders are used for controlled dosing of chemicals, pigments, fillers, and additives in various chemical processes. These feeders also ensure accurate metering of powders and granules during pharmaceutical production.

Limitations of Volumetric Feeders

While the feeders have various benefits, they also have their limitations:

Bulk Density Dependence

The accuracy of volumetric feeders can be affected by variations in the material’s bulk density. Fluctuations in bulk density can cause slight deviations in the actual mass of material dispensed.

Material Flowability

Volumetric feeders may not be ideal for certain materials with poor flow characteristics, such as sticky or cohesive materials. The reason behind this is that they can lead to bridging issues within the feeder.

Key Takeaways

Volumetric feeders play a significant role in ensuring accurate and consistent material dosing across various industries. With their ease of use, versatility, and cost-effectiveness, volumetric feeders are a valuable asset for any operation that requires precise control over dry, free-flowing materials.

By understanding their working principles, benefits, and applications, you can make informed decisions when incorporating volumetric feeders into your production line, ultimately enhancing process efficiency and product quality.